At some of the trade fairs I have already visited this year, there were topics that at first glance only slightly touch on the culinary aspect, but which are nevertheless important from my point of view.

At the International Green Week 2020, for example, I have already seen many producers of new types of packaging, compostable crockery and humidification systems for the retail trade, in addition to exhibitors for food and drink.

At FRUIT LOGISTICA 2020 I decided to learn more about sorting. I had already seen some sorting solutions in passing, but had never taken the time to take a closer look – so industrial sorting was a completely new field for me.

Of course, we all often sort ingredients for their intended use in the kitchen at home. Even if it’s just the fact that we only want to use flawless fruit for garnishing – but it can also have a few spots for cooking jam, which we then “chop out”.

When I visited Hall 9, I took the opportunity to look over the shoulder of one of the most innovative manufacturers of sensor-based sorting machines. A few days earlier I had registered for the press event of TOMRA Food and was warmly welcomed at the stand by Claudia Diedrichsen from Casa Blanca Communication.

TOMRA Food’s trade fair appearance took place in association with two other global players in the industry – at the same time brand companies of TOMRA.

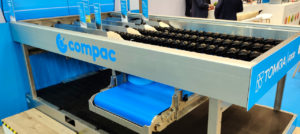

Firstly, Compac, founded in 1984 and currently the leading provider of post-harvest solutions for the fruit and vegetable industry and its spectrim inspectra². Compac was acquired 100% by the TOMRA Group as a brand in 2017.

On the other hand, with BBC Technologies, the world leading New Zealand company for complete turnkey sorting solutions for the optimization & packaging of small fruit. BBC Technologies was also acquired by the TOMRA Group. This company is a real asset especially with its artificial intelligence based tool LUCAi ™ for blueberry classification and the optical blueberry sorter KATO260.

With LUCAi ™, the KATO260 is able to detect poorly visible defects in the fruit, such as drying or pressure marks, ultra-fast and then sort out these specimens accurately.

But first of all, some background information about TOMRA, whose current President and CEO is Stefan Randstrand. TOMRA Food is part of the TOMRA Group and was founded in 1972 – the current CEO is Michel Picandet. TOMRA Food develops and manufactures innovative and resource-saving post-harvest solutions for the food industry.

Many well-known manufacturers worldwide use these professional sorting solutions for fruit & vegetables, nuts, cereals, fish, meat and more in the production, packaging and processing of their products.

The Norwegian TOMRA Group as such started back then with the development, production and sale of reverse vending systems for the automatic collection and recycling of used beverage packaging. Today, more than 100,000 systems are available worldwide from over 80 partners and the company’s annual turnover is over 8 billion Norwegian kroner.

The TOMRA Group is listed in Norway and employs more than 4000 people worldwide. Many of them work in TOMRA Food competence centres, regional offices and at the numerous production sites. Proximity to customers is important to the company, which only will make it possible to sustainably increase customer earnings and to support them promptly with proactive on-site service.

TOMRA Food relies particularly on innovative monitoring technologies such as the SCADA system (Supervisory Control and Data Acquisition). This system makes it possible to identify future maintenance costs for the sorting, classification, peeling and analysis technologies used at an early stage and from remote. Depending on the contract and customer, TOMRA Food then supports its customers’ production in real time.

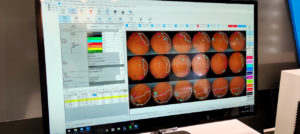

TOMRA Food offers many different solutions for sorting tasks. The TOMRA 5B presented at FRUIT LOGISTICA brings together a wide variety of technical components depending on the configuration. Up to 6 high-resolution cameras enable 360° inspection of the respective product. An off-belt laser, which operates with nine colour and infrared ranges, or other high-end sensor technology can also be added to “spy” on the products to be sorted.

Thus, it is technically possible to detect defects & deviations of only 1 mm size. The TOMRA 5B works with belt speeds of two to five meters per second. It has a frame that can be adapted to the size of the product and can therefore be adapted for each new task in no time at all.

In addition to sorting different sizes, lengths, colours and qualities, one task is often the sorting out of spoiled or even toxic components that have been unintentionally “mixed in” during some harvesting operations.

Compac’s spectrim inspectra² is even able to take the sugar content as a sorting criterion and can therefore, in combination, before and after a TOMRA 5B, ensure that the capacity of the TOMRA 5B can be used optimally.

A decisive factor for this is the UltraView inspection module of spectrim inspectra² – it has a special combination of high-resolution multi-spectral (colour and infrared) cameras and LED lights, which are ideally mounted close to the fruit and parallel to the direction of movement.

Depending on the customer’s task, completely different combinations and sequences in the configuration of the sorting solutions can make sense.

The scalability of the hardware, but above all the associated adaptation of the respective device and management software makes TOMRA Food’s sorting solutions versatile – for example, seasonal changes can be easily accommodated.

With all solutions from the TOMRA Group, the planners and engineers have taken into account that only a few specific actions (quick release fasteners) are required for cleaning and that this means that the process can be carried out quickly and without specialist knowledge, but that an optimum cleaning result is still achieved.

Wherever the fruit comes into contact with the sorters, machine parts made of injection moulded plastic or food-safe stainless steel are used – this ensures that neither fruit acids nor cleaning agents can impair the hygiene and durability of the sorters.

Not only can the proverbial “wheat from the chaff” be separated, but the systems are able to identify any foreign object and eject it in different ways according to its size.

On the TOMRA 5B, for example, high-speed air nozzles remove all unwanted objects from the belt. These are then either sorted out or passed through further sorting machines. To avoid faulty rejects, both pressure and position of the nozzles are automatically adjusted to the type, size and weight of the respective product.

For heavier calibres, TOMRA sorters also use mechanical ejection systems.

With its automated solutions, TOMRA Food makes its individual contribution to reducing food waste – for example, it can quickly identify fruit that is suitable for juice production instead of ending up in compost.

Of course, it should not left unmentioned that my visit to the TOMRA Food stand also included small culinary highlights. Casa Blanca Communication had shown a sure hand in selecting the trade fair caterer – the sweet treats were all remarkably delicious, in addition to their great look!

The topic of sorting is very powerful and I am glad that I was allowed to take a little sniff here. If I was able to bring some light into the “sorting darkness” for you with this article, I am even more pleased.

I was very positively surprised that the topic of sustainability has been the subject of TOMRA Food’s considerations for quite some time now – this ensures that many different types of food do not end up in the garbage or compost during production and packaging for no reason at all.

Many thanks to TOMRA for providing me with product and people photos that I was allowed to use for this article.