First of all, a quick info on my TOMRA interview partner at FRUIT LOGISTICA 2022 in Berlin.

Ken Moynihan, a native of Ireland, has been CEO of TOMRA Processed Food since January 2021. He is an absolute team player and brings to the company more than a decade and a half of experience in leadership roles in high-growth, transformational and scaling structures.

In addition to outstanding technical expertise, Ken consistently exudes positive life energy that has motivated his teams to award-winning high performance over the years. Ken is the Global Player personified and has worked, lived and been inspired by different cultures in South Africa, USA as well as New Zealand. Prior to joining TOMRA, Ken was CEO of Compac, the global leader in fresh fruit sorting technology, which TOMRA acquired in 2016.

TOMRA Processed Food is the global leader in sorting potatoes, nuts, vegetables and dried fruits. One of Ken’s set goals is to stringently change the global food supply chain for the better by optimizing technology.

And culinary? Ken loves all fresh food and is the first to try the dish on the menu that he’s never seen before.

And here we go…

[Erik]: Hello Ken – My name is Erik, I´m managing the foodadvisorblog. Normally I write about culinary things, anything like hotels, food and stuff like this. But my first exception, to write about such a thing like machines, which have a relation to food was TOMRA some years ago – and that’s the reason because I’m here today.

Some of the things which I saw years ago have developed further in the meantime, which aroused my interest. So, at first, I got some general questions to you. This year TOMRA got its 50th anniversary. Congratulations to that. To what extent can the pioneering spirit of the founding fathers still be felt in the company today?

[Ken]: That pioneering spirit remains at the heart of TOMRA Food. We are constantly innovating new solutions, refining existing technologies, and introducing better ways of working closely with our customers – food growers, processors and packers. One of the ways TOMRA Food has grown is through acquisitions of businesses that also have these characteristics.

The pioneering spirit of TOMRA’s founders is echoed in all these parts of TOMRA Food – it’s the same spirit of innovation, growth and opportunity to improve the world that runs through all of them and binds the organization together. This is how we empower our customers to ensure food safety, maximize yield and value, achieve consistent product quality, and minimize food waste.

[Erik]: How have the last three pandemic years affected your ventures? And is the industry now noticeably gaining momentum again?

[Ken]: We took countermeasures to the restrictions on travel and social mixing by doing more for our customers remotely. We expanded our remote service support and introduced live online machine demonstrations, which continue to be available today.

I would say that the momentum has been there throughout the pandemic, it just moved around. The shift from food service to retail was significant throughout the pandemic; now, we’re seeing a move back to food service as it takes off again.

[Erik]: From your point of view, have the markets changed or shifted? What I would like to ask with that, is the business now playing out more in Asia or Australia and less in Europe, has that kind of shifted.

[Ken]: Markets are changing, but not because of the pandemic. There’s a long-term shift in many developing nations, where disposable incomes are increasing, and western-style diets are becoming more popular. This is seen in greater demand for fast food and convenience foods at home. And consumers in many nations around the world are becoming increasingly aware of the importance of sustainability.

Retailers have responded to consumers’ expectations, and they, in turn, expect suppliers to adopt sustainable business practices. With that said, we’ve also seen a major increase in the % of household income that is spent on food – anticipated to almost double from 2017 through next year (2023).

With the additional pressure of war now on globally traded commodities and inputs such as fertilizer, we are likely to see more significant changes and challenges in the coming years. Ensuring the food supply is as efficient as possible will be ever more important.

[Erik]:To what extent has the new branding, i.e., the subdivision of TOMRA Processed Food and TOMRA Fresh Food made noticeable for you?

[Ken]: The key change is that it’s a great story to explain to our customers; who we are, and our history of partnering with them to solve problems; it captures our heritage and demonstrates where TOMRA Food is heading as a leader of the resource revolution.

When you tell the TOMRA Food story and you explain the strength of the whole organization to our customers, they immediately have confidence in who we are and our ability to help them make their own businesses more efficient, more sustainable, and ultimately more profitable. It’s a great story and one we live every day.

[Erik]: Okay. It is certainly also easier for customers to follow the ideas of the company segment that concerns them than it was before with TOMRA as an agglomerate. The reorganization has certainly also made it easier to focus on changes?

[Ken]: Operationally, there are now two business areas, TOMRA Fresh Food and TOMRA Processed Food, each with its own specialized expertise and solutions. We are two parts of TOMRA Food, and we connect to elevate our expertise and talents across both areas where it makes sense, enabling us to leverage our scale and resources across all aspects of our business, without losing the customer intimacy that is critical to delivering real value into our industries.

[Erik]: When did the idea for the TOMRA 5C come about and what was the driving force behind this innovation?

[Ken]: TOMRA’s core competency is in sensing technology: using the latest technology across a range of sensors to know everything there is to know about each piece of food, and allow you to make a decision for each piece, from that rich information.

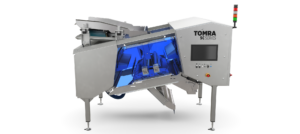

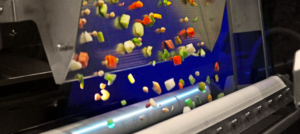

The TOMRA 5C was a logical step forward, integrating the very latest sensing technology with the capabilities of one of our existing freefall sorting platforms, so it was an obvious step for us. The TOMRA 5C answers a big need in the market to see different kinds of defects and different kinds of problems on a range of products – whether frozen vegetables, nuts, or indeed a very wide range of other foods.

[Erik]: From my point of view, the TOMRA 5C is kind of like a masterpiece, especially because it’s so compact. You can do a lot with it and in addition it still looks fancy. Especially the data processing in combination with the sophisticated sensor technology offer a lot of possibilities. That makes this innovation kind of sexy.

[Ken]: Yeah, there’s an extraordinary amount of technology packed into that machine combining high-resolution lasers with TOMRA’s innovative Biometric Signature Identification technology. This means that every object passing down the line is assessed not only for its color and shape, but also its biological characteristics. No one else has this technology.

[Erik]: TOMRA Processed Food talk about biometric characteristics or ‘fingerprint’ of fruits and vegetables – what exactly do you mean by that and what is special about it?

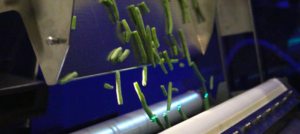

[Ken]: The biometric signature is the different chemical compounds that make up the food and respond to electromagnetic stimulation in different ways. We’re able to sense and understand these differences at high speed, at flow rates of many tons per hour. By doing that, we can really start to separate out with specificity.

Even if two pieces look almost identical to our eyes, we can determine what the different makeup of those pieces is. It’s a sensing technology that’s unique to TOMRA. What’s more, an intelligent software platform sits behind it, allowing you to change how it behaves and separate out the food exactly the way you need it to.

[Erik]: Is it also a self-learning system?

[Ken]: It’s not exactly self-learning, but rather uses the latest AI techniques to learn how to sort. You need to teach the machine, from examples, what you want it to do. It comes pre-set with sorting capability, and then you can teach the machine on top of that how you want to sort right now.

That’s really important, because incoming materials can vary greatly. What happens in the growing season, within a day and a certain region, can suddenly change the characteristics of the incoming product, and it’s necessary to be able to respond to this quickly and accurately. So, you can teach the machine on the fly, by showing it examples, that you want to sort in a different way.

[Erik]: I found what one of your colleagues told me earlier very interesting – namely that there can be situations in which you have almost identical-looking sorting material, part of which can be toxic and must therefore of course be sorted out completely.

Apart of that it would be a fine thing, of course, if a machine could also find out at the same time – I know TOMRA already has sensors for this – how sweet individual fruits are. But due to the high speed of sorting in the 5C, this will certainly be difficult, right? Sequential sampling would certainly make sense here, because the quality and sweetness of the fruit will certainly vary with the deliveries from the fruit growers, which could be kept in view by such tests.

[Ken]: As an example: if you take these three pieces of fruit here – an apple, a pear and a mandarin – we can tell you the sugar content, the sweetness, of all three of those in line, in real time; you don’t need to do it in a lab. We can sense each of these as they travel through the production lines and tell you the Brix [sucrose] level.

[Erik]: And there is no competitor who can do this?

[Ken]: This particular technology has been around for some time, but the ability to do it reliably and consistently at high speed, that’s the core of who we are and what we do – allowing you to have the most accurate and consistent product quality for your customers.

[Erik]: To what extent have you been able to further develop aspects such as remote maintenance, remote process monitoring and the concept of helping customers to help themselves during the pandemic?

[Ken]: The pandemic accelerated a journey we were already on to support and assist our customers remotely.

One example of this is connecting to a machine to diagnose an issue, which became an absolute requirement in the pandemic. We were even able to go ahead with some large installations where we did not have any engineers on the ground: we connected and remotely supported local people who had never seen the machines before, and they were able to get the lines up and running in time for the season. We had that capability already, but it was accelerated. So TOMRA was able to deliver on time and in full, throughout the pandemic.

Another example is the connection to the machines, and the ability to extract data from them. Many of our customers no longer have just one or two machines; some have 25 or 30 machines and they want to be able to see and understand the consistency of the product they’re producing across multiple plants worldwide. See the incoming quality, see what the end product is, maintain consistent quality and then feed information back to growers and forward into the market to adjust how they’re selling their product. That’s been in development for a long time and was accelerated by the pandemic.

[Erik]: I found the demonstration of your online support & training solution very interesting and purposeful. If I were you, I would continue to optimize this approach, regardless of whether the pandemic ends. Because what I personally learned in the pandemic is that online meetings – for example a Zoom or MS Teams meeting – can be much more productive than real meetings – not to mention the travel costs.

You don’t have to talk a lot about incidentals, you can focus more on the real thing. And I think your customers appreciate this kind of help & support. Do you also offer different maintenance levels here, like “Bronze/Silver/Gold” for example – that would be an expandable concept, wouldn’t it?

[Ken]: Yeah, certain customers are very comfortable operating on their own, they want to understand how to manage themselves and do things their way. Most customers desire more support, especially if they are running larger installations with multiple machines. They know their business better than anyone, but we have thousands of installations, we understand the machines and what they can do better than anyone.

So we bring together those two sets of expertise. We help customers hit their business objectives but we don’t tell them how to run their business – they know how to do that, and we help with the technical part of maximizing what the equipment can do for them.

[Erik]: So, it could be a kind of side-business.

[Ken]: Exactly. But we are all in the early stages of a new era of digitalization and interconnectedness, and in the future, there’s a lot more we could and should be doing.

A food processor could work with one of our experts for one hour, and then that expert could move on to the next customer, and the next customer, throughout the day, without having to get on a plane and travel across the world.

[Erik]: It’s a win/win situation. You learn from them and they learn from you.

[Ken]: Absolutely, and that’s the partnership and how we grow together!

[Erik]: I think sustainability and the conservation of resources is something that every company that deals with food should think about. Centuries ago, our ancestors were already aware of how sensible it is to use everything that a farm animal has to offer, for example – here, nothing was thrown away.

Nowadays, the knowledge of respect and the moral obligation to act sustainably is of course even more in focus, because resources are often finite and sustainable action is a question of a company’s image.

Many years ago, the profession of supply and disposal manager was established in Germany. This occupational group had and still has the task of putting the supposed waste products of a production process to a sensible and, ideally, profitable use – in other words, to think about what we can do with the things that are left over. In the case of fruit production and sorting, this can be the stems of the fruit that are put to further use.

There was an interesting cooperation in Germany, for example, with regard to the spent, wet coffee powder, as it is produced daily in the many coffee chains. Here, a few innovative minds brought to life the idea of filling tetra packs with it and selling them to the end consumer, spiked with fungal spores and ecologically sealed. The customers open the whole thing at home so that air can get in, add some water if necessary and then have mushrooms of their choice freshly harvested in their own kitchen in no time at all.

[Ken]: Absolutely, there’s an extraordinary amount of waste in the system. In the global system today, people are taking the lowest hanging fruit, the easiest yield, and then moving on. When you start thinking deeply about what resources can be used and how, as the population is booming and the middle class is growing around the world, we’ve only got one world and most of the arable land is already used. How do you feed people? How do you make sure you meet the demand for food?

[Erik]: It’s interesting because 100 years ago, or even 1000 years ago, that’s what they were doing – our ancestors were acting sustainably. Apparently, on the way to today, we somehow lost the ability to act that way, and now it’s coming back.

[Ken]: Absolutely, as we continue industrialization, the first wave took the lowest hanging fruit. And now we’re coming back through the cycle and finding much more value through smarter technology and more effective, sustainable practice.

[Erik]: Thank you Ken – I’m done with my questions to you. There were a few more than I had noted down in advance, but the interview with you was informative and gave me a lot of pleasure.

Your openness and your direct and refreshing manner certainly contributed to the fact that it was so entertaining. I wish you continued success at FRUIT LOGISTICA and will take the opportunity to take a few snapshots of your machines afterwards. Especially of course of the blue gullwing doors – almost like the old Mercedes-Benz SL models – of the TOMRA 5C.

[Ken]: Thanks Erik, it’s been a pleasure – so take the photos and at best, leave us some of your innovative ideas. But wait, as a savvy food blogger, surely you can give us a tip on the best place to eat in the city tonight?

[Erik]: Tonight? Of course, I have a good steakhouse in mind for you, but honestly, I assume that you will certainly not be able to eat properly today in the context of the fair. But we can plan something for your next visit to Berlin. Until then, all the best for you and stay healthy!

[Ken]: That’s probably right, then gladly next time. Thanks Erik and see you soon!

[Erik]: I would be glad – see you!

This interview took place on April 6, 2022 at FRUIT LOGISTICA 2022 in Berlin. ©foodadvisorblog